powder coating installations

Powder coating

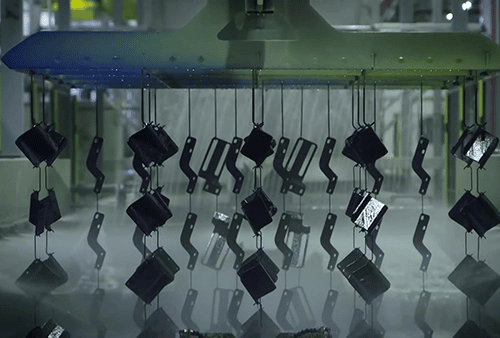

A powder coating installation or powder coating line consists of one or more sub-processes where we always begin with a good pre-treatment. In an increasingly demanding market, more and more companies are concluding that an additional process such as KTL/ATL or galvanising becomes necessary to keep up with higher quality demands. In all cases, a drying oven is required after the pre-treatment. A nice and even layer of powder coating is then applied in the powder booth, which hardens in the curing oven into a wear-resistant and hard protective layer. The powder coating process is therefore a succession of processes that need to be perfectly coordinated with each other, and that is precisely what we have in-house knowledge for.

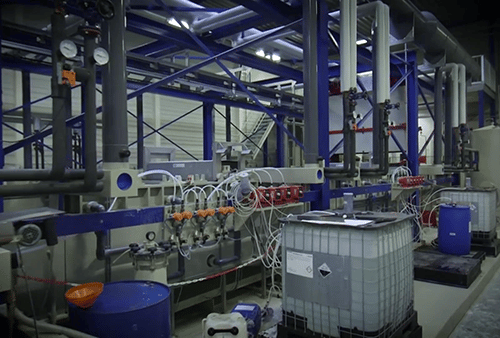

Pre-treatment

Without a good pre-treatment, there is no high-quality powder coating process. Depending on the quality requirements of your products and the materials used, you can choose for blasting or wet chemical pre-treatment.

Indufinish offers a wide range of products, varying from plastic and stainless-steel baths to spray tunnels and multi chamber cleaners. We have the expertise to realise the perfect solution for your situation. Sophisticated design of the various spray phases guarantees an optimal pre-treated product in steel, aluminium and galvanised steel. As standard, our spray pumps in the pre-treatment installations are fitted with frequency converters in order to optimise energy consumption and to be able to set the correct spray pressure. This prevents unnecessary energy loss through throttling valves. Needless to say, that we are in constant contact with the chemical suppliers, in order to keep up to date with the latest process developments.

Heating and cooling

Precise temperature control in both pre-treatment, galvanic and KTL/ATL baths is very important for proper process reliability and film thickness composition. In addition to external heat exchangers for heating a bath, you can also choose for heat exchangers in the bath, for strong chemical processes made of plastic. Both can be supplied with central heating water or electrically. Cooling systems are carefully designed by us, where good fluid exchange and good cooling is achieved through heat exchangers and an innovative piping system with eductors.

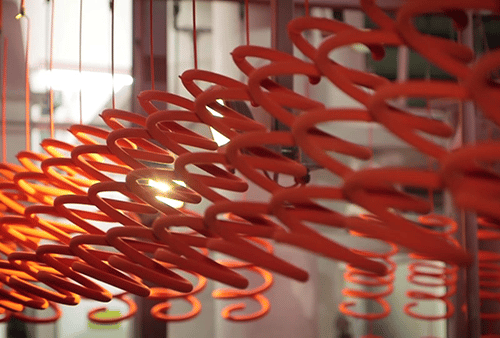

Powder spray booths

Indufinish has been the market leader in the design and manufacture of powder spray booths for many years. Our plastic powder booths are made of high-quality sandwich panels. The precise degree of finishing the powder booth, in combination with the excellent properties of the plastic used by us, makes an extremely short cleaning time possible.

Our powder booths are available in various versions; the hard colour change times vary from 4 to 15 minutes, depending on the version and options, including the cleaning of spraying equipment and cyclone. All additional equipment such as spraying equipment, powder feed centres, vibrating sieves, powder containers (possibly in plastic), powder pumps and big bag feeding stations can be integrated in virtually every installation.

Throughout the years, we have developed several robotic applications for touch-up spraying and loading or unloading products on to a moving chain conveyor. Although automatic spraying with automatic reciprocators can already be a considerable gain in the efficiency of your installation, there is still room for further improvement. We enjoy working and thinking together with you and we are an innovative partner when it comes to automating/robotising your powder coating line.

Drying ovens & curing ovens

Indufinish designs drying and curing ovens with an operating temperature between 35 and 220 °C. The drying and polymerisation processes of water, powder coatings and electrophoresis paints fit within this temperature range. Materials such as wood, plastic, steel and non-ferrous metals are heated evenly during the process until the coating has dried or hardened. Which heating system we use, depends on the type of coating and the available energy sources (gas/electricity). In all concepts (air circulation, IR or so-called dark radiation ovens) we carefully study the possibility of heat recovery and, where possible, we apply it. Uniform heating in combination with active air locks or automatic doors in the product entrance and exit openings, are key concepts in the drying and curing process. They have a major impact on your energy consumption. We guarantee the engineering of air distribution and air locks in such a way that your energy consumption is kept to a minimum.

Indufinish b.v. | Willem Barentszstraat 5 | 7825 VZ Emmen | The Netherlands | +31 (0) 591 630 003 | info@indufinish.com